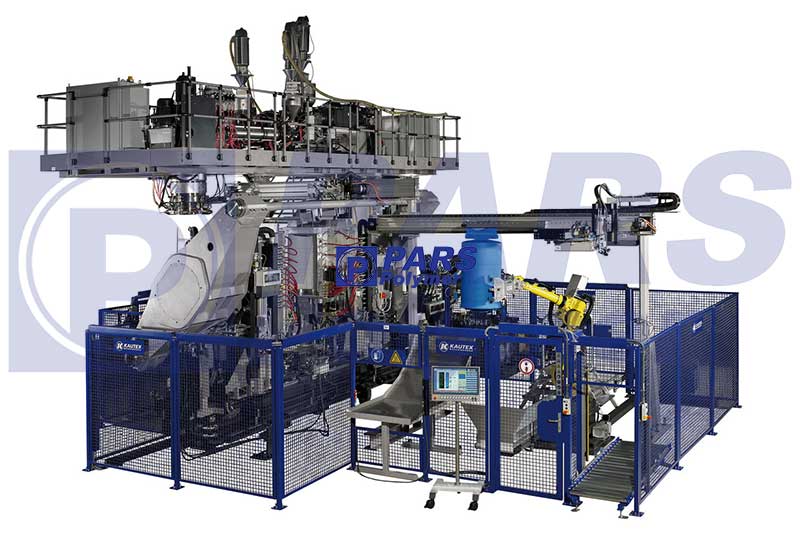

60 liter blow molding machine with unlimited possibilities, suitable for producing all kinds of products, including fuel tanks, storage drums and barrels of different sizes, plastic chairs, plastic tables or parts for agricultural industries, the very durable range of this The machines attract you with a high output rate and can be adapted to your business needs. The modular base with continuous improvement and numerous successful projects speak for the quality of this device.

All blow molding machines are available as single or dual station machines and can be equipped with a comprehensive processing system, shuttle operation or the long-proven Parison robot transfer depending on your needs.

High performance blow molding machines for sustainable production of hollow plastic parts

Today, our customers use a wide range of our production systems to manufacture various containers such as bottles, plastic cans, fuel tanks, composite pressure tanks and more. Reducing your production costs is a key consideration during our development processes. To achieve this goal, we are constantly trying to optimize the production time and reduce the amount of materials. It is also important to us to guarantee you the highest possible degree of system stability, user-friendliness and availability.

Innovative solutions during the production process ensure that you get exceptional product quality while minimizing downtime. With Blowmolding’s extrusion technology, we help you permanently strengthen your market position with individual possibilities for configuration and quick-change systems to increase production efficiency. We will also support you with fast, comprehensive and focused nationwide service.

Features of the 60 liter blow molding machine

It is performance oriented yet affordable. We have continued to develop hydraulic extrusion blow molding machines continuously for generations. Popular blow molding machine are manufactured in our factory and offer a wide range of possibilities for use, from packaging, automotive to special applications. We can provide you the most cost-effective solution for all of these.

When developing the third generation of Blowmolding extrusion models, we didn’t just modernize the design. We also optimized and added several technical features. This allows you to enjoy the most attractive technologies in the world today. Most machines are available as single or dual station. Clamping forces vary from 60 kN to 400 kN.

The performance and advantage of the 60 liter blow molding machine

Suitable for producing 15-100 liter barrels and tanks of different sizes, with open mouth

Suitable for the production of tanks and other chemical packaging products.

Adopting high-output extrusion system, single-station and two-station accumulator die head.

Optional display bar line system.

Optional hydraulic servo control system.

Specifications of the 60 liter blow molding machine

The capacity of the machine is up to 60 liters

The production is about 55 pieces per hour

Parts with imported famous brands for the device

Suitable hydraulic valve for stable performance

The extinguishing system can be equipped according to the customer’s request.

Accumulator dye head, single layer, capacity up to 60 liters

It processes materials such as HDPE, PP, ABS, etc.

Power supply: VAC 380, Hz 50

Extrusion system:

Helix: Specially designed based on material characteristic, high quality nitrogen steel 38CrMoAlA, with nitrogen level HV≥800, brittleness≤2. Barrel: high quality nitrogen steel 38CrMoAlA, with nitriding surface HV≥900

Die head: Accumulator die head, single cylinder, central injection, smoothness of the accumulator channel. Sliding parts such as injection pistons and cylinders made with different materials and techniques are balanced and reliable.

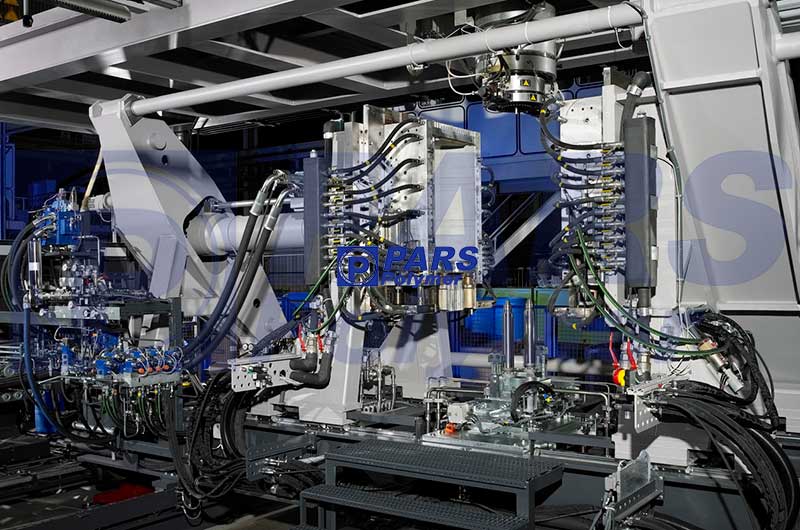

Clamping system:

Fixed clamp system, double diagonal rod single cylinder center clamp, wider space for mold, mold installation and removal easily, linear guide rail.

Hydraulic system:

Adopted proportional pressure control, with hydraulic valve, balanced and precise operation, long service life

This machine is mainly used to produce 60 liter drums, chemical drums and oil drums. Some of the basic parameters are as follows:

Screw diameter: 90mm

2.L/D ratio: 1/30

Maximum capacity: 60 liters

Dry cycle: 180 pieces per hour

Clamping force: 320KN

Open stroke of the plate: 450-1050 mm

Mold plate size: 900*880 mm

Oil pump power: 15 kW

Extrusion motor: 37 kW

Plasticizing capacity: 140 kg per hour

Heating zone: 4 zones

Extrusion heating power: 21.3 kW

Die head heating power: 21.4 kW

Maximum diameter of mold pin: 350 mm

Other advantages of the 60 liter blow molding machine

1) Adopt energy saving system which can increase 18% efficiency.

2) The capacity is about 55 pieces per hour, which is 15% more than some others.

3) Electricity consumption is about 15% less.

4) All processes are well computerized which makes the operation more convenient.

5) Imported hydraulic parts that ensure stable work for a long time.

after sales service

1) Installation and troubleshooting instructions

Before delivery, Danesh Banyan Pars takes responsibility for debugging the device to ensure that the provided device can be used safely and smoothly.

2) User training

Before delivery, we take the responsibility of technical training to the operator so that they can understand the features of the machine and can operate the machine by themselves.

3) Warranty period

The warranty period of the device is one year with long-term maintenance. If the user requires a specific quality warranty, another specified warranty period may be established upon mutual agreement.

Dear artisans, to get advice and guidance for setting up a production line of all kinds of plastic products, contact our consultants through communication channels.