What is PETG ?

PETG or polyethylene terephthalate glycol is a thermoplastic polyester commonly used in the production of PETG bottles and containers. PETG is a part of PET that is commonly found in plastic bottles of drinks and food products. G stands for glycol, which increases durability and strength, and helps with impact resistance and the ability to withstand high temperatures. Despite a market seemingly dominated by PLA, PETG has quickly become a popular choice among 3D printing enthusiasts for several reasons.

What are the advantages of PETG bottles and containers?

The first and most obvious feature of PETG is its strength, durability and flexibility, which makes it an ideal choice for industrial products. PETG also has high impact strength and heat resistance, making it an excellent raw material for food containers and medical products. With relatively low cost, recyclability and water resistance, PETG is introduced as a suitable option for the plastic industry.

According to the technical details, PETG has a glass transition temperature of 85°C, a nozzle temperature of 210-250°C, a heated bed of 80-100°C and a melting point of 260°C. With this in mind, these raw materials make for strong yet flexible products that can withstand a number of environmental stressors.

In fact, PETG has quickly become a popular choice among packaging and container manufacturing options due to its odorlessness, good layer adhesion, and low shrinkage rate.

While the average cost of PETG can be higher than other similar raw materials, such as PLA or ABS, its benefits far outweigh its costs. As mentioned earlier, it is completely recyclable. Secondly, its odorless quality makes it a suitable alternative to ABS, which is notorious for its unpleasant fumes.

The added glycol modification prevents corrosion and crystallization effects and makes it easier to manufacture than PET products. Unlike PLA, PETG is water resistant, allowing it to last in harsh outdoor environments. Since it is produced at a higher temperature than PLA, it is also more heat resistant.

What is the use of PETG?

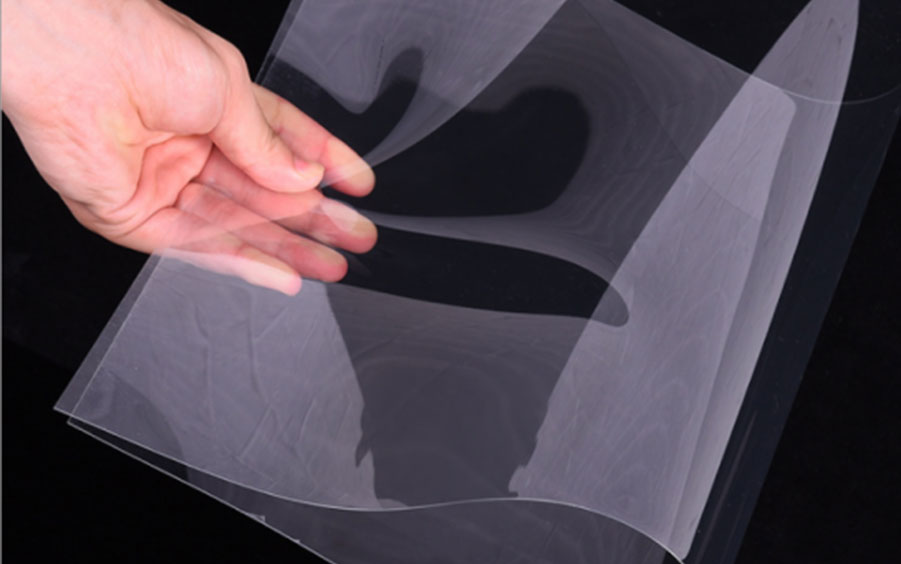

One of the common uses of PETG is for the design, prototyping and production of PETG bottles and containers. Its high impact resistance and durability make it an ideal option. PETG is also BPA-free, which is good news for consumers of products like baby food containers and water bottles. These elements, along with the natural transparency of PETG (even more transparent than PET), explain how it has become a popular choice in the food and beverage industry.

However, PETG is not just for food packaging. PETG is durable enough to withstand the harsh chemical and radiation sterilization processes required in a medical environment. Its transparency and durability also make it perfect for medical and pharmaceutical packaging.

In addition, PETG is also used in implants and medical prostheses.

Businesses that want to be unique in the market have good reason to use PETG in their signs and displays. Clear plastic can be easily painted to create eye-catching shop signs. It is also used in creating display stands of different colors and sizes (instead of jewelry).

Because of its tough resistance to heat and chemical stressors, PETG is also used by machinists and manufacturing engineers to create parts such as guards, test parts, and manufacturing tools and aids.

Differences between PET and PETG

PET is the result of combining two monomers. PETG may contain the same monomers, but it also contains glycol, which gives it different chemical properties than PET. PETG is less brittle and more flexible than PET, making it ideal for bottle production.

PET and PETG are similar materials and both are equally easy to recycle, but there are a few important differences. PET is less affected by UV rays than PETG, and PET is very scratch resistant. Additionally, PET is an easier material to work with, so if you choose PETG, you should find a packaging supplier with a lot of experience working with PETG plastic.

However, PETG can be an excellent choice for many packaging products, including a variety of PETG bottles and containers. It’s more transparent than PET, meaning it’s easier for customers to see your product. PETG is more durable and impact resistant than PET and feels softer to the touch, which can appeal to consumers. It is also more resistant to chemicals than PET.

Molding of PETG plastic bottles

Molding of bottles and PETG plastic products is done by special PETG inflatable plastic machines.

All kinds of PETG plastic bottles in different sizes and shapes can be produced by these inflatable plastic machines.

Get in touch with our experts to get advice and guidance for setting up the PETG production line through communication channels.

The website’s user feedback system encourages transparency and helps build a reliable community of buyers and sellers.