When it comes to modern industrial machinery, the rotary screw air compressor is one of the most widely used technologies. Renowned for their reliability and versatility, screw compressors are the workhorse of many industrial processes and applications. This durable technology is suitable for a range of demanding industry tasks, without these types of compressors, businesses around the world would face operational challenges and efficiency issues.

There are two basic principles for compression in air compressors. One of these is the principle of positive displacement. There are many types of compressors that use this method, with wind screw compressors being the most popular.

How screw compressor works

As the name suggests, rotary screw air compressors use rotary motion to compress air. Inside the compressor there is a set of male and female rotors. They will be designed differently so that when they are rotated in unison, air is trapped between them. The male rotor has convex lobes and the female rotor has concave cavities. In this way, they can be connected to each other to be compressed. Additionally, the male rotor will have slightly fewer lobes than the female, meaning it spins faster and effectively drives the female rotor.

Unlike reciprocating compressors that use the same compression principle, the screw element of the screw compressor is not equipped with a valve. As such, it can operate at high shaft speeds and there are no mechanical or volume losses to create an imbalance. This means that screw technology can combine high flow rates with a compact and space-saving design.

Work steps of screw compressors

An opening valve sucks the gas into the compressor chamber. Two screw rotors are located in the housing. When the device is on, they spin at high speed.

As the impellers rotate, they trap and separate air in the cavities between the rotors, thus moving the air down the housing.

The size of the chamber decreases and moves away from the opening valve. As volume decreases, pressure increases.

Pressure builds up and as a result the air condenses.

Air pressure causes the compressor discharge valve to open, allowing pressurized air to enter a receiver or other holding tank.

The air is compressed and can be transferred to the required equipment such as dryers, pneumatic plastic machines and oil/water separators for drying and contamination removal.

Advantages of screw compressor

As the technology of choice in a wide range of applications, screw compressors have many advantages to offer customers:

Continuous operation – capable of continuous air flow and pressure, no need to turn off and on, and no duty cycle. This means they can work continuously with little or no downtime.

Easy maintenance – with very few moving parts and contact, wear and friction is minimized. Long service intervals reduce maintenance costs and make any routine checks and repairs quick, easy and hassle-free.

Powerful performance – Screw compressors can work in challenging conditions because they have high air flow rates and can operate at high temperatures. This means they can operate pneumatic tools and heavy equipment easily and efficiently.

Energy Savings – After standing the test of time, these durable machines generate less heat and conserve more energy than other models. These design features mean that they do not degrade compressor capacity over time, keeping the lifetime cost of the compressor low.

Low noise – silent operation is due to the small size of the units and the absence of moving parts, which makes them suitable for installation in various locations.

Oil screw compressor

Lubricated screw compressors, sometimes called rotary screw seal or oil injection, use lubricant inside the compression chamber to cool and lubricate the compressor element. The lubricant helps seal formation and also has an excellent noise reduction effect.

Oil-based air compressors are reliable, durable and efficient, and are suitable for a variety of production processes. Downstream equipment such as air and oil filters and dryers can remove any oil contamination from the finished product and create a clean compressed air stream suitable for construction work, waste management, bottle blowing machines, recycling and much more. .

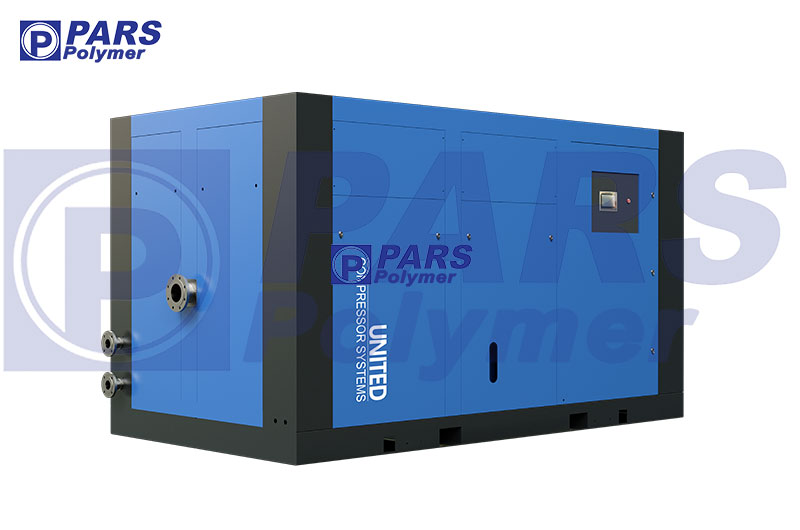

Pars Company offers a full range of lubricated screw air compressors from 2 to 250 kW with air flow from 0.24 to 47 cubic meters per minute and pressure range from 5 to 13 bar.

screw compressor oil free

Oil-free screw compressors use no oil in the compression chamber, effectively eliminating the risk of contamination. When air purity is critical to your business and even the smallest amount of contaminants can disrupt your process, or even ruin your finished product, oil-free compressors offer peace of mind. For pollution-free air, rely on oil-free screw compressors.

Oil-free compressors from Atlas Copco, Phinney and other reputable brands use low- and high-pressure dry screw impellers that are individually driven by variable speed motors to provide unmatched levels of energy efficiency. The groundbreaking design is compact, saves space and doesn’t compromise performance. In fact, these compressors consume 37% less energy than a typical oil-free two-stage compressor.

Other compressors in our oil-free range include United Japan and Kaishan compressors that offer 100% air purity to customers. In these models, quality water is used for lubrication, cooling and sealing of the compressor as an oil substitute. By completely removing oil from the process, you can ensure dry air output for a range of demanding industries such as chemical, pharmaceutical and food & beverage. It is an excellent choice for applications where compressed air comes into direct contact with the product.

Another choice is the fixed speed rotary screw dry compressor. These two-stage models are designed to provide safe and reliable performance in the toughest conditions. Offering advanced performance with low life cycle costs, it is ideal for industrial compressor installations.

Buy screw compressor

Many businesses rely on screw compressors for their daily production capacity. These compressors are suitable for heavy duty industrial operations due to their robust design and duty cycle. Common industries where screw air systems support you are sectors such as automotive, inflatable plastics, food packaging, aerospace, construction, and more. They are ideal for both small and large scale operations as they can withstand a wide variety of operating conditions, making them an excellent choice for many professionals.

To buy all kinds of screw compressors and high pressure compressors 30 bar and 40 bar from the best brands in the world, contact our experts through communication channels.

I appreciate the option to create a wishlist, making it easier to keep track of desired items.

I appreciate that the website allows users to set their preferred currency, accommodating international users.