Plastic injection molding and injection blow molding is an integral process for creating plastic parts for several applications. This technique requires a set of materials as well as types of plastic injection molds and inflatable plastics. Injection molds are generally classified according to their characteristics, including the feeding system, the number of cavities or cavities, and the mold plate.

Each plastic injection mold used for the injection machine has its own characteristics in each category. For example, you can have a three-panel mold that has a cold runner system and multiple cavities. Therefore, it is very important to understand each type of plastic injection mold and air plastic mold in injection molding to choose the right one for your projects.

All components have unique designs. Therefore, your choice of mold depends on the plastic parts you need to make. In this article, we discuss the types of plastic injection molds and inflatable plastics and what they include. Before we get into that, let’s review the different components of plastic injection molding.

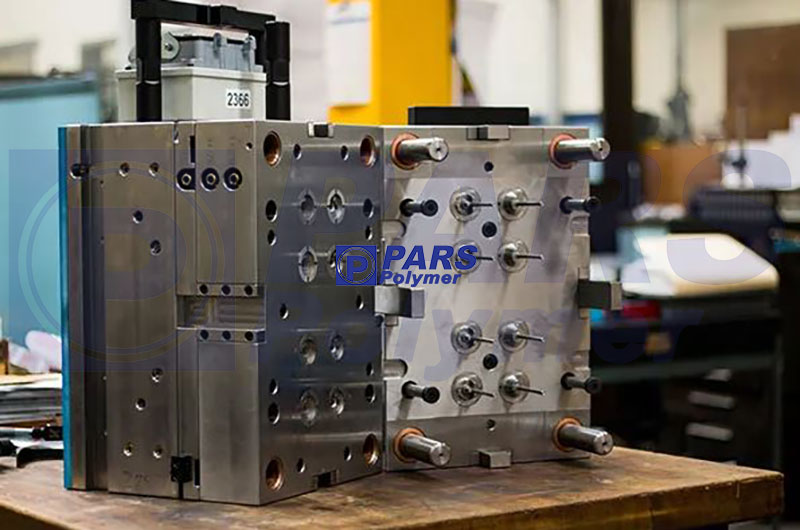

plastic injection mould

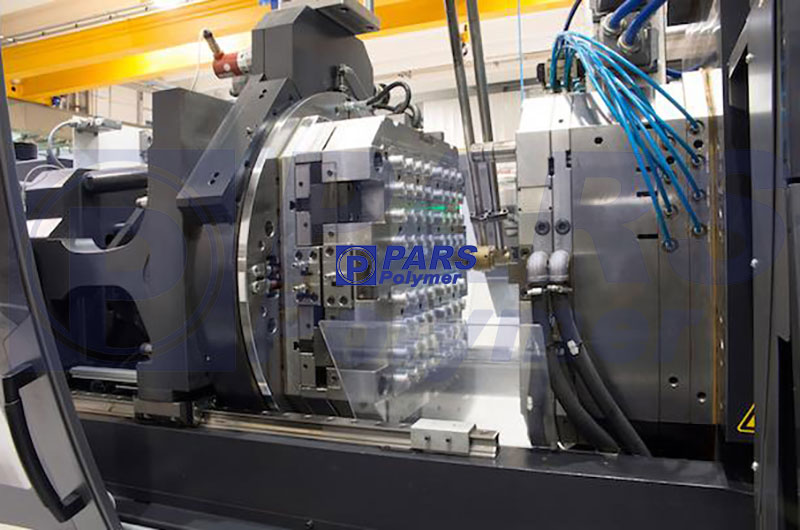

Multi-cavity injection mold

Plastic injection molds help in the molding process. Custom mold may be created with aluminum or steel for efficient results. They often consist of two parts – fixed molds and movable molds.

Fixed molds are installed on the fixed plates of molding machines while movable molds are on the movable plates of the machine. Both fixed and movable molds remain closed during the molding process to create the injection and cavity system. Once opened, the machinists remove the molds to separate the products.

Plastic injection mold components

The structure of plastic injection molds is often different based on the properties of the materials, the types of injection molds and the structure of the final products. However, the basic structure is the same.

Guide pins

Mold cavities and mold core halves are opened and closed several times during the production of plastic parts. Therefore, guide pins and bushings in injection molding help ensure perfect alignment of the mold halves when the mold is closed. They support the mold plates to prevent distortions that could damage the mold or cause injection molding defects.

runner

Sprues and runners work together at the beginning of any injection molding process. The plastic material in the runners flows through the sprue bushing. Individual runners then take the plastic to the point of entry into the molding cavities.

Gate or mold entrance opening

The injection molding tool has a gate design that allows molten plastic to be injected into the injection molding cavity.

The design of the injection molding gate, its type and location affect the appearance, dimensions and warping of the parts.

Sprue

The sprue nozzle supports injection molding – the nozzle is placed on the surface of the sprue bush. As a result, it acts as the first path for the distribution of liquid plastic in the mold.

ring

The rim is placed on the sprue bush. This works in such a way that it places the mold in the right position on the molding machine. Thus, it ensures proper alignment of sprue bushing and nozzle to eliminate leakage.

The cavity of the plastic injection mold

The mold cavity is the inner part of the mold that is machined to obtain the desired final product shape. The machinist injects molten plastic into the mold cavity to create the finished product. Some molds (e.g., multi-cavity molds) often have multiple cavities with balanced feed systems to prevent defects.

Plastic injection mold ejector pins

These precision pins combine with the ejector plates to effectively remove the parts from the mold after cooling. After the components have cooled, the mold is opened and the ejector pins help push the final product out of the mold.

shot

Shot is a volume of plastic material that fills the mold cavity, creating a pressure cushion and compensating for shrinkage. It helps transfer pressure from the screw to the mold cavity.

Plastic injection mold ejector plate

The ejector plates provide a base for installing the ejector pins. The plate moves forward so that the pins also move forward and push the cavity or core.

Plastic injection mold clamp plate

The clamping plates help connect the mold halves to the molding machine to begin the injection molding process. The injection molding tool has two large clamping plates that close when the machinists inject the plastic into the cavity. When the plastic part has cooled enough, the mold is opened and the part is allowed to fall from the mold halves.

Buying all kinds of plastic injection molds

There are different types of injection molds based on different features. Choosing the right plastic injection mold for your project is very important. The mold affects the speed of production, the overall costs and the quality of the final products.

Contact our experts to choose and buy the right mold for your products.

The platform’s integration with mapping services allows for easy location-based searches and directions.