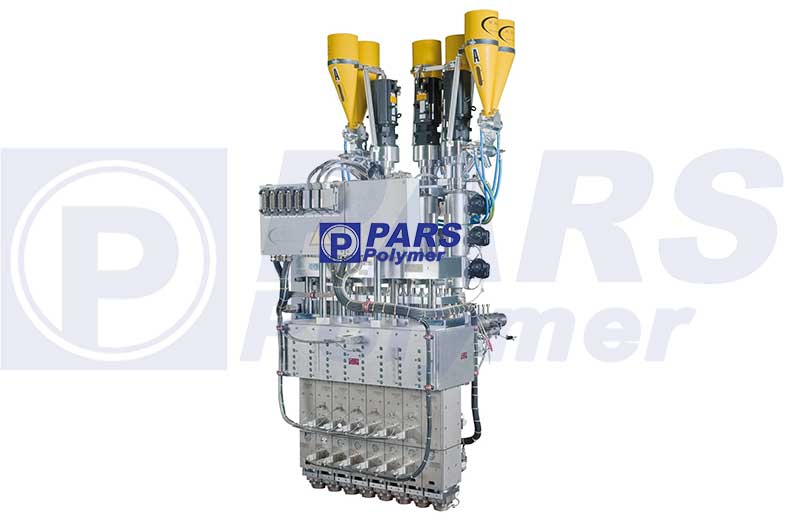

die head is a equipment for extrusion blow molding machine on designs or heart-shaped manifolds. With these designs, flow and welding lines are inevitable. However, spiral mandrel manifolds are capable of producing parisons with a homogeneous material structure around their perimeter. Pars Company supplies spiral mandrel die heads for single-layer and multi-layer molding products, for continuous parison extrusion heads and accumulator die heads, single or multiple dies. Coextrusion die heads with 4 or 6 layers are a proven highly desirable solution for the body molding of multi-layer plastic fuel tanks and multi-layer filler tubes for automotive applications. We also offer two-layer systems.

Features and benefits of die head

Concentric spiral mandrel manifolds with complex melt predistribution and optimal layer composition

Very compact size and very light weight

Great versatility in terms of materials, total power and layer structure

Ambient layer distribution even without any streamlines

Excellent cleaning

Fast start-up and shutdown processes, very short warm-up times, cleaning steps and cool-down times

Most usable materials and modern surface coatings

die head specification

The produced mold designs have a mold output diameter from 10 mm to 1000 mm and a total output power from 10 to 1850 kg/h. The supply range can include adapters for connecting die heads and extruders, die assemblies (quick change systems as an option) and hydraulic cylinders for parison thickness programming. Small 4- and 6-layer die heads for multi-layer products can be equipped with the radial wall thickness programming mechanism designed by us.

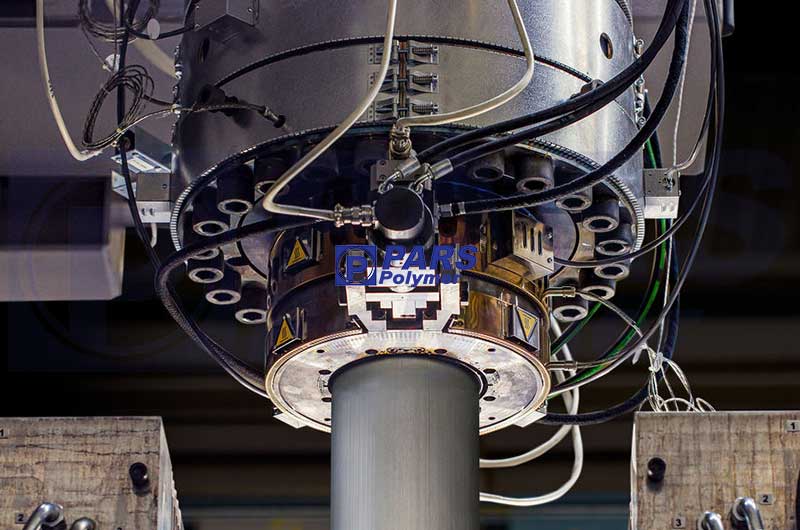

The die head consists of a perforated plate, a smooth connecting tube and a core assembly. Die heads commonly used in blow molding machines include straight die heads, die heads, and die heads with storage cylinders.

Among them, the straight die head direction corresponds to the helix axial direction. When the melt flows through this mold, the flow direction is unchanged. This type of die head can be used for air molding of heat-sensitive plastics. Rigid PVC bottles are often obtained using this mold for blow molding.

In a die head with a storage cylinder, the melt is first stored in the tank, and when the storage amount reaches a certain value, it is extruded and molded together. Since a sufficient volume of melt can be stored in the cylinder, a die head with a storage cylinder can be used to produce large blow molding products.

The die head is a part that plays an important role in the production process with an inflatable plastic machine, especially for multi-layer plastic products.

Features die head with storage cylinder

The use of a die head with a storage cylinder can ensure that each layer of the multilayer product can be perfectly formed, thereby ensuring that the manufactured products have a uniform distribution of wall thickness.

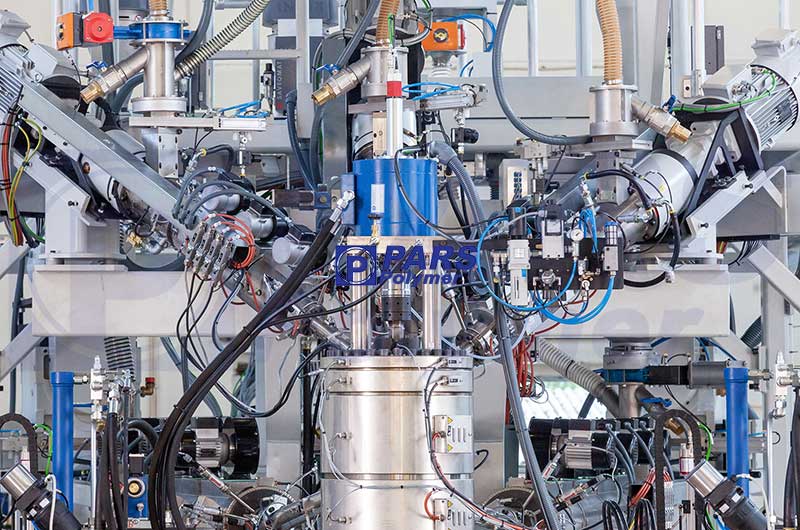

At the same time, it is not affected by material distribution, and different plastic raw materials can be processed and adjusted according to different extrusion amounts.

The multi-layer structure of the head meets the needs of specific products. It can meet the technological needs of different flow rates and different materials.

The rheological design of the die head is key in the production process. It can not only have good self-cleaning performance at low extrusion volume, but also has low shear heat at high extrusion volume.

Buying all kinds of die heads for extrusion Blow molding machines

To buy single or multi-layer die heads, single and multi-layer die heads, accumulator die heads of Bloemolding’s plastic air extrusion machine, contact our technical experts through communication channels.