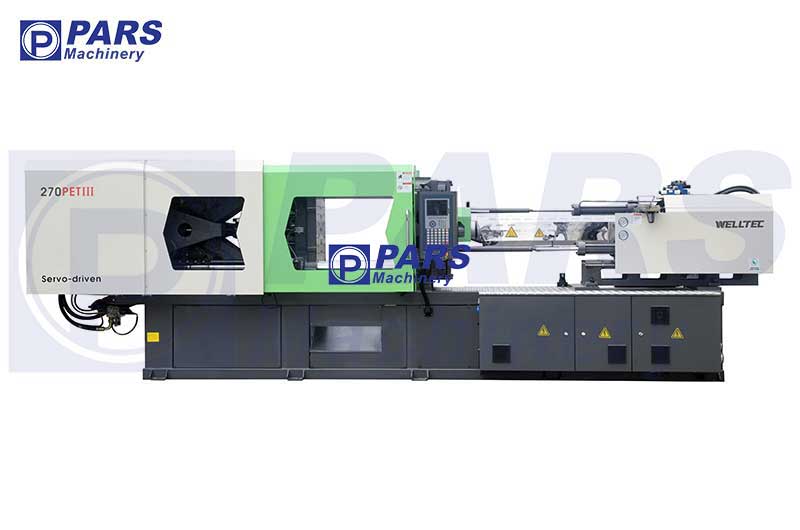

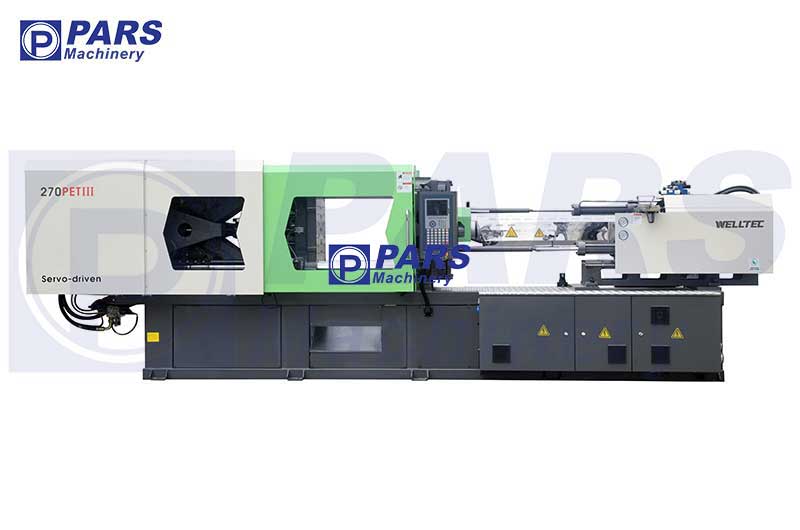

The preform PET injection machine is designed and produced according to the molding technologies of PET materials, including the special design of the spiral and barrel, precise controller of barrel heating, tie bar space, nozzle, launch system, enlarged motor, oil pump, etc. . All kinds of PET preforms including PET bottle preforms, hot bottle preforms, wide mouth glass preforms and 3-5 gallon bottle preforms can be produced with PET plastic injection machine.

Pars Machinery Company has rich experience in various fields of PET preform injection technology. We design PET preform injection machines for the purpose of producing all kinds of preforms or other PET products and offer optional options. We check all the factors such as: dehumidification of raw pet, additive color composition, production capacity, stable performance, even connection with blowing machine or other subsequent steps, then provide you with professional solutions according to your budget and request. We present. Our PET preform injection machine is suitable for forming preforms of mineral water, carbonated drinks, fruit juice, edible oil, pharmaceutical cans and lotions, cosmetic packaging containers and other preforms.

Advantages of PET injection molding machine

Fast and efficient

PET injection machine with special design on large clamping force. Intelligent PLC system: The system provides faster transmission and faster feedback during work. High-speed multi-purpose application supports high-speed mold movement and other equipment. High-speed movement: By increasing the displacement of the oil pump, the power of the servo system improves the movement speed of the injection machine, including charging, injection, mold opening and closing, and the ejector. Efficiency of the hydraulic circuit system: The efficiency of the preform injection machine is 15-20% higher than the normal injection machine by optimizing the oil and milk path, which greatly improves the output capacity.

Reliable and energy saving

PET preform plastic injection machine uses excellent system, which can solve the problem of high vibration of mold unlocking and uneven operation, thus affecting the life of the machine and bringing optimal performance. Set an open and close template key. Mold opening is fast and smooth to reduce machine wear. Impact-free high-pressure clamp to extend the life of the device. The hydraulic system fully uses imported hydraulic components of famous brands, which improves the oil circuit by combining inserts and slide valves, and also effectively increases the system response speed and speed. PET shot weight range from 777g to 3350g machines to choose exactly what you need and other energy waste.

Completely optimized design and high efficiency of PET injection machine

clamping unit

Increased stiffness and clamping force The connecting rod is one-piece and completely cast, so to ensure good strength and smooth movement, the post lock shaft remains fixed during opening and closing, thus reducing mold wear. Self-lubricating bushing is used. Remarkably, due to its specific wear resistance and low friction coefficient. Lift service increases the draw bar. Complete auxiliary solution for high speed PET injection molding system. (3 in 1 mold dehumidifier)

Injection unit of preform PET injection machine

A larger spiral designed for PET materials creates a large injection weight. The spiral L/D ratio is 24:1, which is better for plasticizing PET materials. Hydraulic motor with better winding ceramic heater for better energy saving PID temperature control for injection unit

buy PET injection molding machine

The purchase price of preform PET injection machine is determined according to the features and options, including the most important feature of production speed and daily production rate of the product. Contact our experts 24 hours a day for information on prices and advice.

Pars Machinery Company has rich experience in various fields of PET preform injection technology. We design PET preform injection machines for the purpose of producing all kinds of preforms or other PET products and offer optional options. We check all the factors such as: dehumidification of raw pet, additive color composition, production capacity, stable performance, even connection with blowing machine or other subsequent steps, then provide you with professional solutions according to your budget and request. We present. Our PET preform injection machine is suitable for forming preforms of mineral water, carbonated drinks, fruit juice, edible oil, pharmaceutical cans and lotions, cosmetic packaging containers and other preforms.

Pars Machinery Company has rich experience in various fields of PET preform injection technology. We design PET preform injection machines for the purpose of producing all kinds of preforms or other PET products and offer optional options. We check all the factors such as: dehumidification of raw pet, additive color composition, production capacity, stable performance, even connection with blowing machine or other subsequent steps, then provide you with professional solutions according to your budget and request. We present. Our PET preform injection machine is suitable for forming preforms of mineral water, carbonated drinks, fruit juice, edible oil, pharmaceutical cans and lotions, cosmetic packaging containers and other preforms.

I’ve had success in connecting with local service providers through the classifieds section.