In general, the parison control system is not only the controller, but also the parison thickness control system.

A parison is a hollow tube-like piece of molten plastic through which compressed air can enter.

Applications of parison control

There are many methods for making plastic containers, such as molding with an extrusion machine, injection molding, rotational molding, etc. Among the molding methods, many plastic containers are produced by molding with an inflatable plastic machine.

Due to the introduction of inflatable plastic machines, 80 to 90% of hollow containers in the world are produced with inflatable plastic machines.

Extrusion molding technology is to form a plasticized parison against the inner wall of the mold by air pressure.

The parison is produced by extrusion, that is, the plastic melt is heated and plasticized, and extruded through a core gap of various shapes to form a cylindrical parison of various shapes.

The extruded parison is suspended vertically by its own weight. The minimum wall thickness is specified, and the basic inflatable plastic equipment does not have a parison wall thickness control system.

In order for the thinnest part of the product to reach the minimum required wall thickness, other parts of the product must be thickened in the same proportion, and as a result, the material is wasted.

In order to save costs, reduce the cooling time of products and speed up the production cycle of products, Parison wall thickness control system is more economical.

For example, a 50-liter tank, the net weight of the product produced by the conventional machine is 3.5 kg to reach the minimum wall thickness, and by using the Parison controller, the net weight of the product is reduced to 2.4 kg. And it meets the minimum required wall thickness, saves 20% to 30% raw materials, and the products produced are uniform and thin.

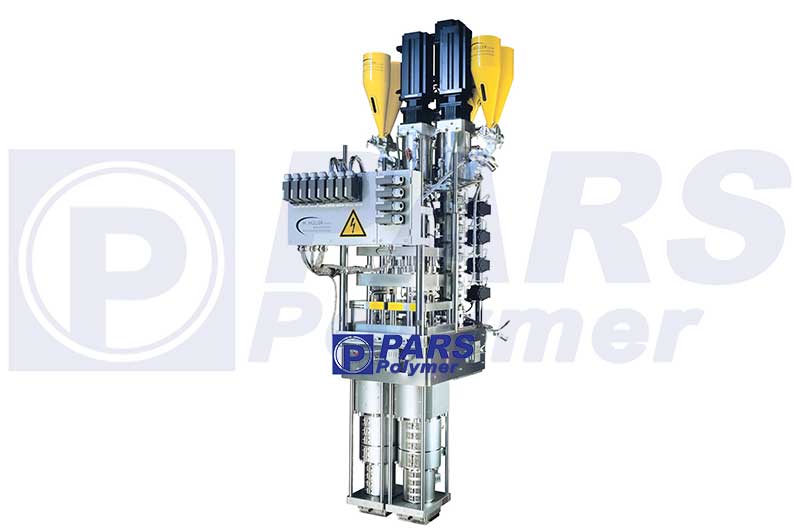

Parison control system components

This system consists of the following components:

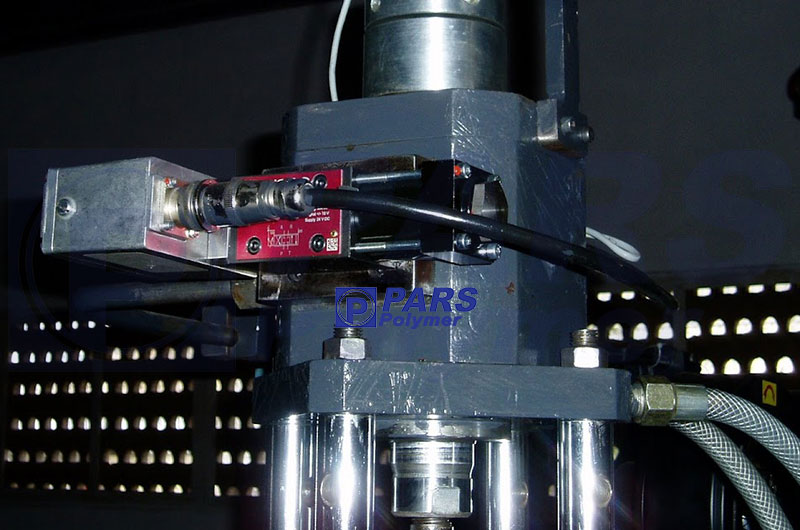

1. Parison hydraulic cylinder 2. Oil tank 3. Precision filter 4. Pressure accumulator (does not necessarily depend on the product type) 5. Parison controller 6. Hydraulic cylinder control valve 7. Engine hydraulics.

Parison control MOOG

MOOG is one of the brands of Parison control system. Main parts 1. Parison control system 2. Hydraulic cylinder control valve.

Because of its high reputation and high market share, MOOG has been adopted by the industry as the generic name for the Parison control system. In the hydraulic generation, MOOG has almost monopolized the parison control system market. However, in servo motor production, MOOG did not rank as highly as it did and shared a smaller market share for its typical performance.

What are the Parison control systems used for?

The main application of the parison control system is to change the thickness of each section for a gallon/bottle/extrusion molding product from top to bottom.

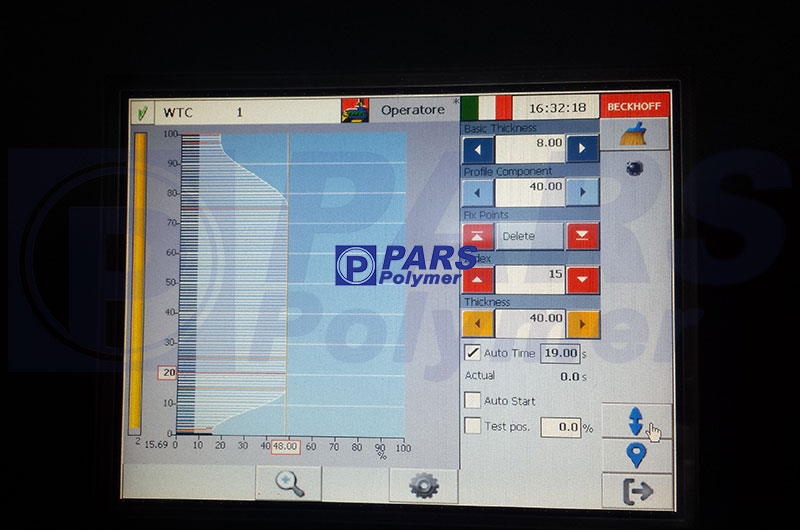

The number of sections depends on the capability of the controller, valves and servo motor. 100-point control parison is the most common, that is, there are 100 sections from top to bottom, and the thickness of each section can be adjusted separately.

What are the advantages of Parison control system?

We can use the parison control system to change the thickness of each part for the product of the blown plastic machine, including all kinds of container, bottle extrusion from top to bottom. Therefore, the following are among the advantages of this system.

1. Changing the thickness of the bottle / to change the weight of the bottle / product without changing the mold.

2. Thinner the body which does not affect the strength of the bottle, reduce the weight to reduce costs.

3. Thickening the mouth, bottom and handle of the bottle which is easily broken or deformed and strengthens the product.

4. With the function of relative thinning and increasing the cooling speed of the product, the production cycle time can be shortened and the output can be accelerated.

5. Adjusting the thickness of each part of the products that customers need, makes it possible to make some products that cannot be produced before.

Do you need a parison control system for your inflatable plastic machine?

It depends on your budget and your client’s needs. In general, if your project is for long-term production, we suggest installing the Parison control system. This system strengthens the product, reduces the cost of materials, accelerates the production process and makes products with more complex design. which will cause better competition in the market.

Servo or hydraulic? Which type of parison control system is better?

The servo motor is an advanced Parison servo control system, and the power supply can be adjusted according to the actual situation when power is needed. Accuracy is higher and more power is saved. Oil tank and precision filter are not required, so maintenance cost is lower than hydraulic type. For long-term consideration, the cost of using a servo-type parison control system is lower than that of a hydraulic type.

Compared to the hydraulic type, the only disadvantage of the servo type is the higher price. If the price difference is within your budget, we suggest you choose the servo type.

Features of Parison Control

High resolution analog functions allow precise control and positioning

The modular design with a capacity of up to 2000 I/O means that the controllers can be optimally configured to suit applications of all sizes.

The real-time Linux-based operating system combines true multitasking with fast response time and also makes it easy to add PC-like features.

A standard development environment with debugging, simulation, parameterization, and tracing capabilities makes programming and testing fast and simple.