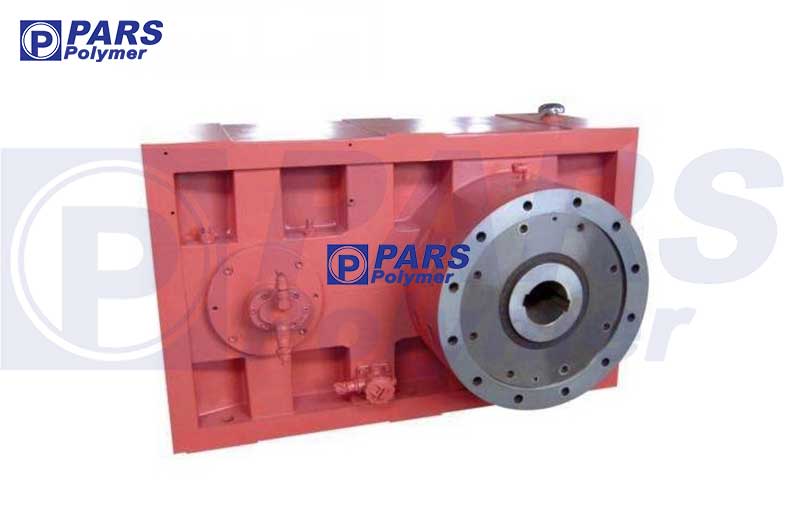

The most basic definition of a gearbox is that a gearbox is a box containing a large number of gears or a mechanical unit or component consisting of a series of integrated gears in a housing. In fact, its translation defines its essence – a box containing gears. In its most basic sense, the ZLYJ extruder gearbox works like any gear system. It changes torque and speed between a drive device such as a motor and a load.

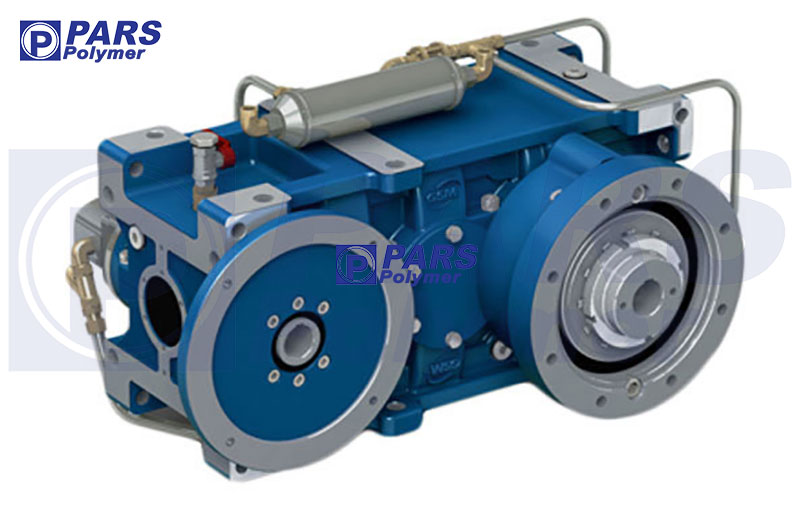

Extruder gearboxes consist of hardened gears, available in dual, horizontal and parallel shaft models, which are usually designed to meet the specific conditions and requirements that typically occur with the extrusion process. The gear units have a superior ability to transmit high torque, which is essential for compression and plasticization of molding materials, and can also be used to absorb high axial loads with the help of integral spherical roller bearings. The pivot bearing housing attached to the main case is adapted to have suitable thrust bearings and equivalent output shafts.

All gear teeth are manufactured with appropriate profile modification in accordance with the most modern method using computer aided techniques to develop greater efficiency and transmission capacity. These gears are heat strengthened by being enclosed in modern sealed furnaces.

Features of ZLYJ extruder gearbox

Made of alloy steel, they are strong in design

It can withstand heavy loads

It requires little maintenance

Computer aided design provides excellent accuracy

Accurate performance

Low noise

Higher torque increases output

It is durable and can work for a long time without the need for service or replacement

Efficient operation

Excellent transmission efficiency helps to transmit more power

Applications of ZLYJ extruder gearbox

Oil refining and petrochemical industry

Auto Parts

Wind turbines

Inflatable plastic industrial machines

ZLYJ extruder gearboxes are used in many applications including machine tools, industrial equipment, conveyors, and indeed any power transmission application with rotary motion that requires a change in torque and speed.

So it is clear that a gearbox is always a fully integrated mechanical component consisting of a set of gears mated in a housing with a shaft and bearings (to support and lift loads) and in many cases a flange for mounting the motor.

All kinds of industrial gearboxes

Helical gearbox

Helical gearbox is an energy-efficient gearbox and is compact in size. This equipment is used for a wide range of industrial applications, but is typically used in heavy duty operations. Helical gearboxes are popular in plastic, rubber and other heavy industrial machines. It is also used in crushers, extruders, coolers and conveyors, all of which are low consumption.

The helical gear is unique in that it has a fixed angle that enables more teeth to interact in the same direction as it moves. This feature provides permanent connection for a specified period of time. Extruder helical gearboxes are used when torsional stiffness must be maximized and are very useful for low-noise operations. Extrusion gearboxes are used in plastic injection industries and machines that require high mechanical strength.

Spiral linear gearbox

Coaxial helical gearbox is ideal for heavy duty applications. Coaxial spiral lines are noted for their quality and efficiency. These gearboxes are manufactured to a high degree of specification which allows you to maximize the load and transmission ratio.

Conical spiral gearbox

The important feature of this type of gearbox is the set of curved teeth that are located on the conical surface near the edge of the unit. Bevel-helical gearboxes are used to create rotational movements between non-parallel shafts. These types of gearboxes are usually used in mining machinery and conveyors.

Diagonal helical gearbox

The bevel helical gearbox is notable for its solid and integrated construction, which makes it suitable for heavy loads and other applications. These industrial gearboxes have many mechanical advantages when installed on the correct motor shaft output. These gearboxes can be adjusted based on the number of teeth and gears. Therefore, you can easily find the right gearbox for your needs.

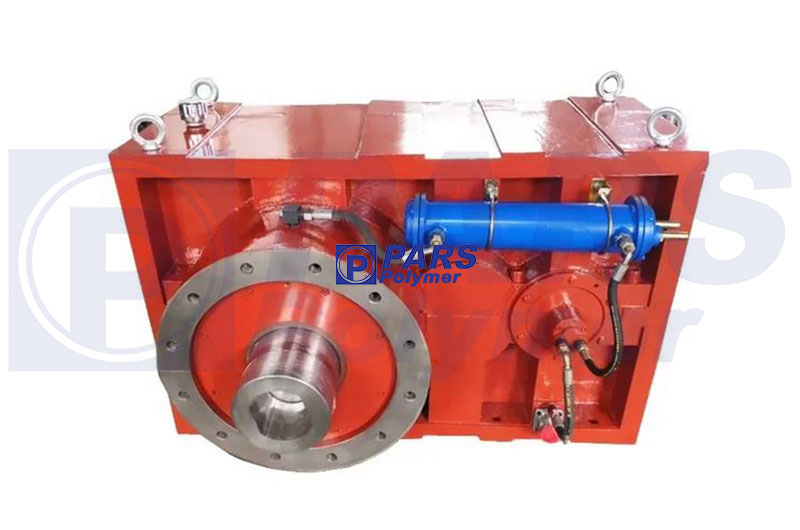

Reducer ZLYJ Extruder Gearbox

Reduction gearboxes are used to drive heavy operations. Helical gearboxes are used when there is a need to reduce the increased speed between non-crossing axles. In this type of industrial gearbox, worm gears are used, which have a large diameter. The worm or screw meshes with the teeth of the peripheral area of the gearbox. The rotary motion of the worm causes the wheel to move similarly due to the screw-like motion. Most of these industrial gearboxes are used in heavy industries such as fertilizers, chemicals and minerals.

Planetary or solar gearbox

A solar or planetary gearbox is ideal for its endurance, precision and distinctive performance, and is remarkable for its precise applications. This type of gearbox increases the life of your equipment and optimizes performance. Planetary gearboxes are available in a hollow core type or with a variety of mounting options including flange, shaft or base.

Buy ZLYJ extruder gearbox

Industrial gearboxes are available in various sizes and models and are manufactured by various brands. You can contact our experts to buy the best and highest quality gearboxes for plastic injection machines, blow molding machines and other industrial equipment and benefit from technical and expert advice for free.