Every day, people around the world deal with millions of bottle caps. Some lids of medical and health bottles contain medicines, while others are used on bottles of mineral water and soft drinks. The production of plastic bottle caps must be done in a special way for the same application.

Types of bottle caps

A bottle cap can be defined as a packaging device whose purpose is to ensure that the contents of a container remain in that container until it is ready to be used. The exterior of the bottle cap is usually textured to make it smoother and easier to open, and usually has a lip at the bottom of the cap. In some cases, the top of the cap is embossed, which usually includes instructions on how to open the bottle (in the case of pharmaceutical bottles) or the shape of the company logo.

Plastic bottle caps, such as those found on water bottles or medicine bottles, usually have an internal thread that matches the external thread on the neck of the container to hold the cap in place. The thread inside the cap is specified in terms of tpi or threads per inch, and the number of threads used depends on how secure the cap is. In addition, there are standard threads, skirt sizes, and cap sizes that make it easier to use to match caps to bottles.

All kinds of raw materials for the production of plastic bottle caps

The vast majority of plastic bottle caps are made from recyclable plastics, the four most common of which are:

PET (polyethylene terephthalate), which is strong and light, is often used for bottle caps of mineral water and soft drinks.

HDPE (High Density Polyethylene), which is tough, rigid, but still lightweight.

LDPE (low density polyethylene), which is flexible and has excellent impact resistance.

PP (polypropylene), which is tough, rugged and durable, is commonly used for all kinds of bottle caps.

However, other plastics may be used. Due to the widespread use of bottle caps, the use of recyclable materials is very common. When choosing the raw material used for the bottle cap, you should consider characteristics such as how long it will be used (for example, a cap for a single-use water bottle as opposed to a cap for an expired bottle that is intended for a month). taken does not require high resistance), among other effective factors in the selection of raw materials is the type of product involved (liquid, powder). Also note that all materials used for bottle caps in contact with drugs, foods or beverages must be food grade polymers.

Molding and injection to produce plastic bottle caps

Most plastic bottle caps are produced through a process called injection molding with plastic injection machines. In this process, thermoplastic polymer pellets are heated in a metal hopper until they become very soft and pliable. (This is where any custom coloring is already added). The softened plastic is then injected under highly controlled and high pressure into a complex and precise steel mold. The mold shapes the softened polymer into the desired shape for bottle caps. Once the polymer material has cooled enough to harden, the mold is opened and the bottle caps are removed. If several doors are made from the same mold (as often happens), they are carefully separated from each other and prepared for further processing (for example, for gasketing, sealing, etc.).

Injection molding is a very good method and the most common method of producing bottle caps. For example, injection molding is very cost-effective for high volume production. Also, high repeatability and increased production are other features of production with plastic injection machines, which means that there will be virtually no change in the size, shape, or surface finish of the doors.

Bottle cap mold for plastic injection machine

Injection molds can be very durable, which can be very important when threading.

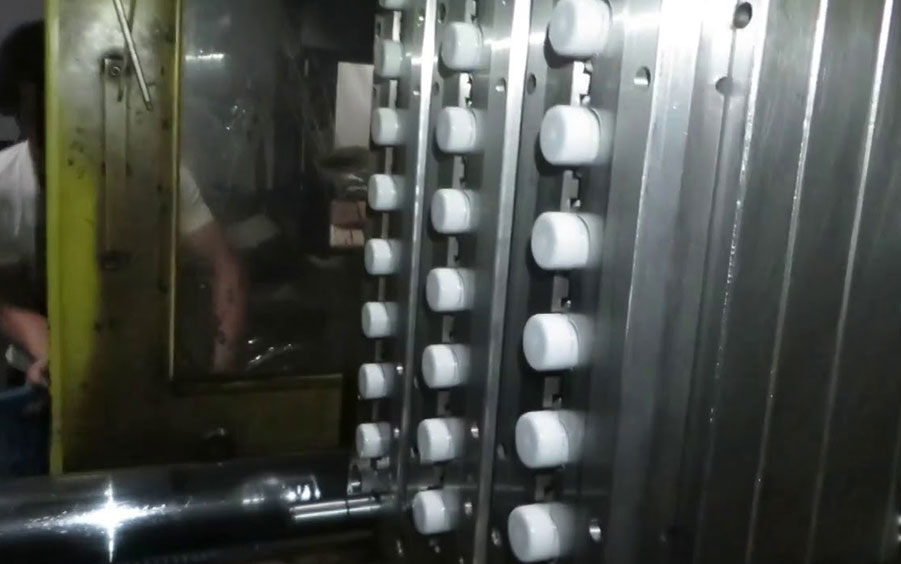

The molds themselves are often machined from durable stainless steel and are used thousands of times in a production run. As seen in the figure above, each mold is designed to make multiple bottle caps per use. Their design is much more than the geometry required to achieve the final shape of the bottle cap. Not only must they be held together tightly enough to withstand thousands of pascals of pressure during processing, but they must also eject the parts without damaging or leaving marks on them after the cycle is complete.

Plastic injection molds are made to very precise dimensions and require as much skill as possible from the tool and mold makers who make them. In the case of bottle caps, the molds themselves have the reverse shape of the bottle cap, including the thread and anything embossed on the top or sides of the cap. It is important that these design details remain dimensionally stable as the part cools in the mold, so the mold must be designed so that the part cools evenly inside the mold to avoid distortion of the final shape.

The price of the bottle cap injection molding machine

Most of the cost of making a bottle cap is invested in the molds used, which is why injection molding is often used for high volume production.

Bottle cap molds are expensive due to the complexities involved in achieving the internal thread, which are considered undercut parts, and require special tooling and mold design considerations to allow the parts to be machined after cooling without Separated damage. However, when a manufacturing company has already invested in high-quality, sophisticated molds for standard bottle cap sizes and threading, it can quickly recoup initial costs with high production volumes.

Design and relief on the plastic caps

A prominent message, company logo, slogan, address or warning – or any combination thereof – can easily be added to the top of the plastic bottle cap. In fact, this option can eliminate the need for labels and can include cross-promotion or product warnings.

Embossing also serves as a great way to grab the attention of customers or users who may ignore the label but can’t ignore the cap when opening the bottle, especially when the embossing is combined with custom colors. . Plus, the embossing is long-lasting after the label is lost or accidentally removed. Due to the ease of incorporating embossing into the bottle cap manufacturing process, there is usually no additional cost.

Sealing plastic bottle caps

The lining material between the bottle cap and the contents of the container is called wad and can serve various purposes. The gasket can act as a seal to protect the integrity of the contents, protecting them from moisture or oxygen. It may be considered as an extra piece to ensure that the contents stay inside the container. In the case of a product such as medicine, evidence of tampering can prevent someone from ingesting something that could make them sick or poisoned.

You’ve probably come across polycell lids that have a sponge pad called a polycell handle on top of the lid. Foil sheets or laminated wads are polycellular bundles that have a foil layer to protect the polywad from any chemicals in the bottle and support chemical compatibility.

Production of plastic bottle caps

Plastic bottle caps are very different and diverse. Among the most used types, we can mention rotating, push, disk, button, etc. caps, which are produced in various sizes and dimensions.

Pars Polymer is a producer of all kinds of plastic bottle caps using the highest quality raw materials. Also, the affordable and competitive price of Pars Polymer products is one of the distinctive features of our company.

Contact us for free advice and guidance.

I’ve recommended this website to friends and family who were looking to buy or sell items locally.